Operation

Operation

Cargo Hold Cleaning for M/V Queen Sarah

Company

Reederei Nord Group

Company

Reederei Nord Group

Company

Reederei Nord Group

Services

Cargo Hold Cleaning · Chemical Cleaning · Hold Painting

Services

Cargo Hold Cleaning · Chemical Cleaning · Hold Painting

Services

Cargo Hold Cleaning · Chemical Cleaning · Hold Painting

Industry

Agribusiness · Chartering · Shipmanagement

Industry

Agribusiness · Chartering · Shipmanagement

Industry

Agribusiness · Chartering · Shipmanagement

Year

2023

Year

2023

Year

2023

Seachios® Marine Services executed a full hold cleaning at Pecém (22–27 Jul 2023) using 500-bar hydrojets and Unitor™ Aquatuff™. After inspection, we escalated to repainting at Vila do Conde (27–29 Jul) to ensure grain-clean acceptance.

Capt. Ji Feng

Master of the M/V Queen Sarah

An excellent job was carried out on board M/V Queen Sarah, with strong cooperation between the shore team and the vessel’s crew. I highly recommend the cargo hold cleaning services provided by Seachios® Marine Services.

Executive Summary

Vessel: M/V Queen Sarah

Previous cargo: Coal

Next cargo: Grains (Vila do Conde)

Locations & dates: Team embarked 21 Jul 2023 at Pecém; cleaning 22–27 Jul; vessel proceeded to Vila do Conde; repainting 27–29 Jul.

Methods: 500-bar high-pressure water jetting; application of high-alkaline marine degreaser (Unitor™ Aquatuff™) per OEM guidance; freshwater neutralization rinse; controlled waste handling; full repaint decision based on blackstain persistence and grain-clean standard.

Complication: Unloading equipment at Pecém physically abraded coal against the steel, embedding residues and scoring the coating, intensifying blackstain.

Outcome: Holds restored by repainting, achieving visual uniformity, corrosion protection, and charterer acceptance for grain.

Operation Timeline & Scope

Embarkation (21 Jul, Pecém): Shore team mobilized; toolbox talk, JSA/RA, confined-space gas test, and permit-to-work issued.

Gross Cleaning (22–23 Jul): Removal of loose residues; mechanical sweeping; suction and wash-down to expose impacted areas.

Chemical Phase (24–26 Jul):

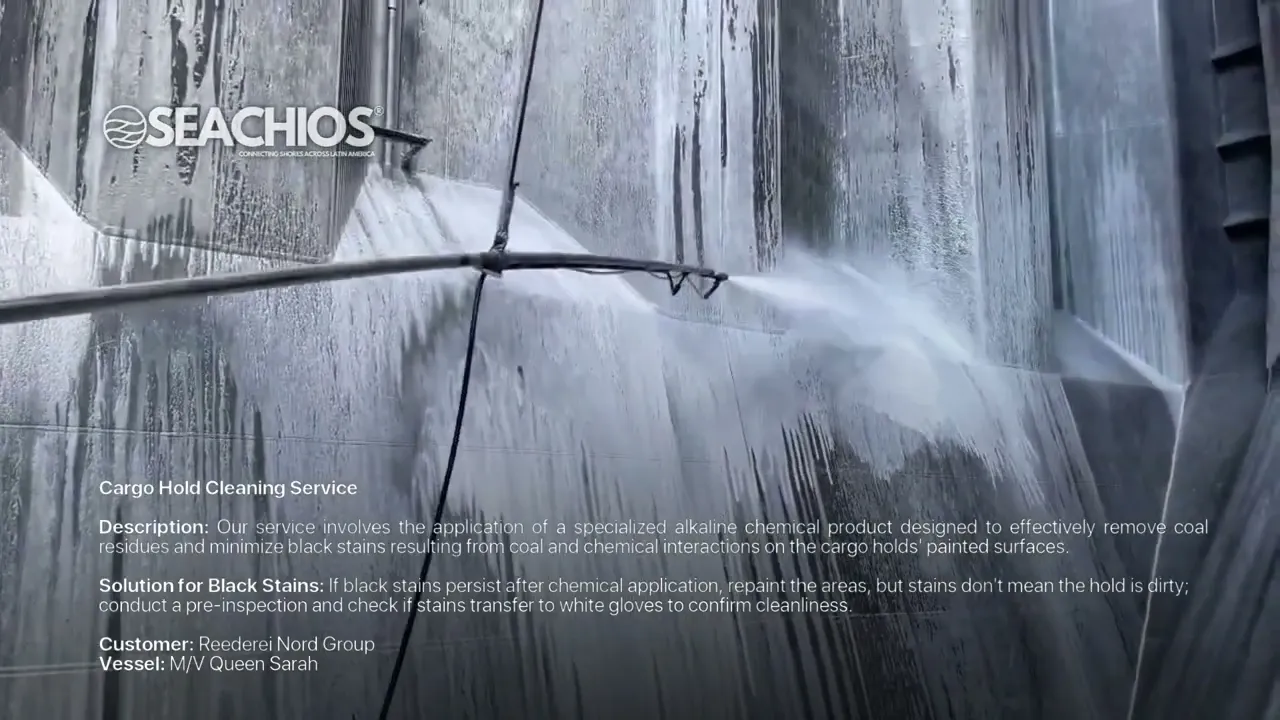

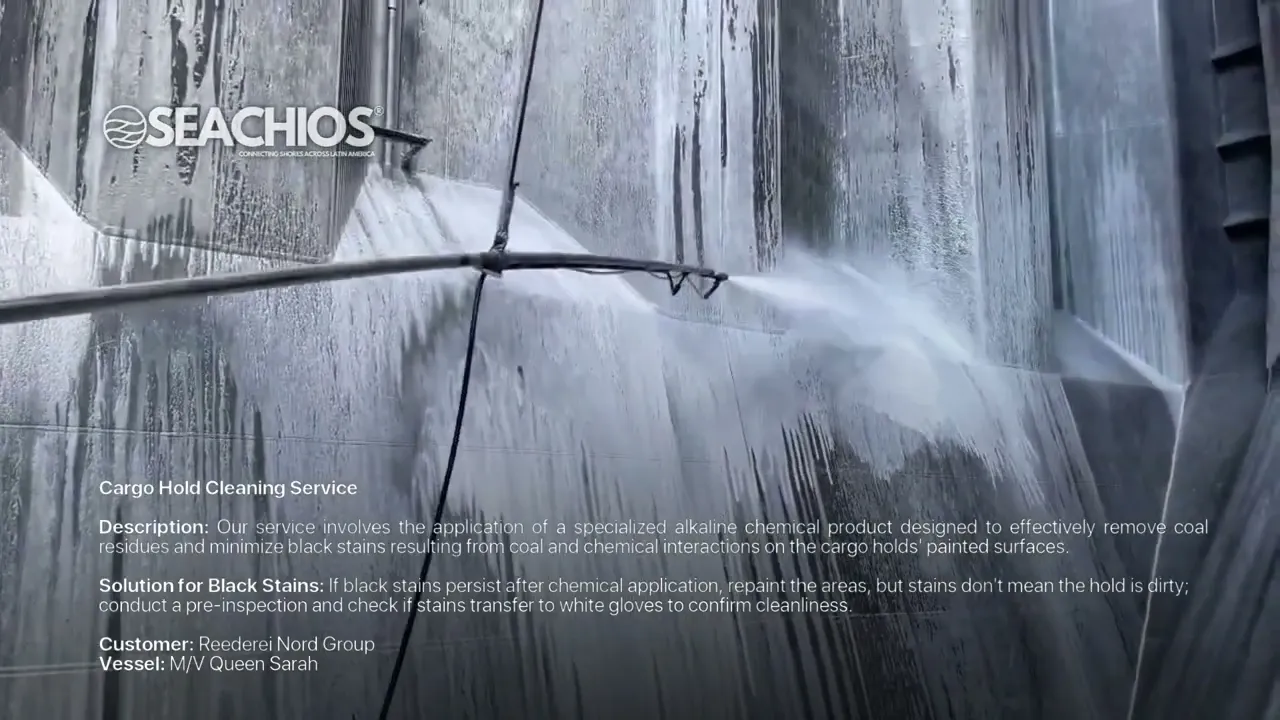

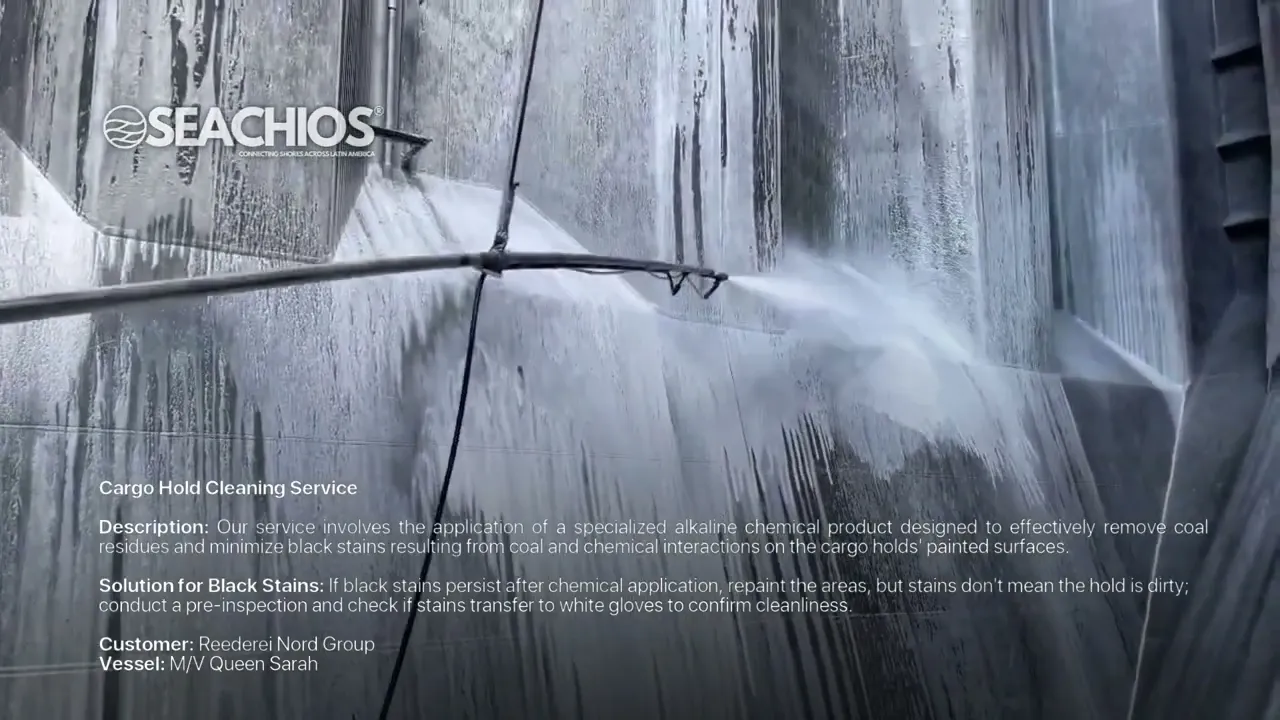

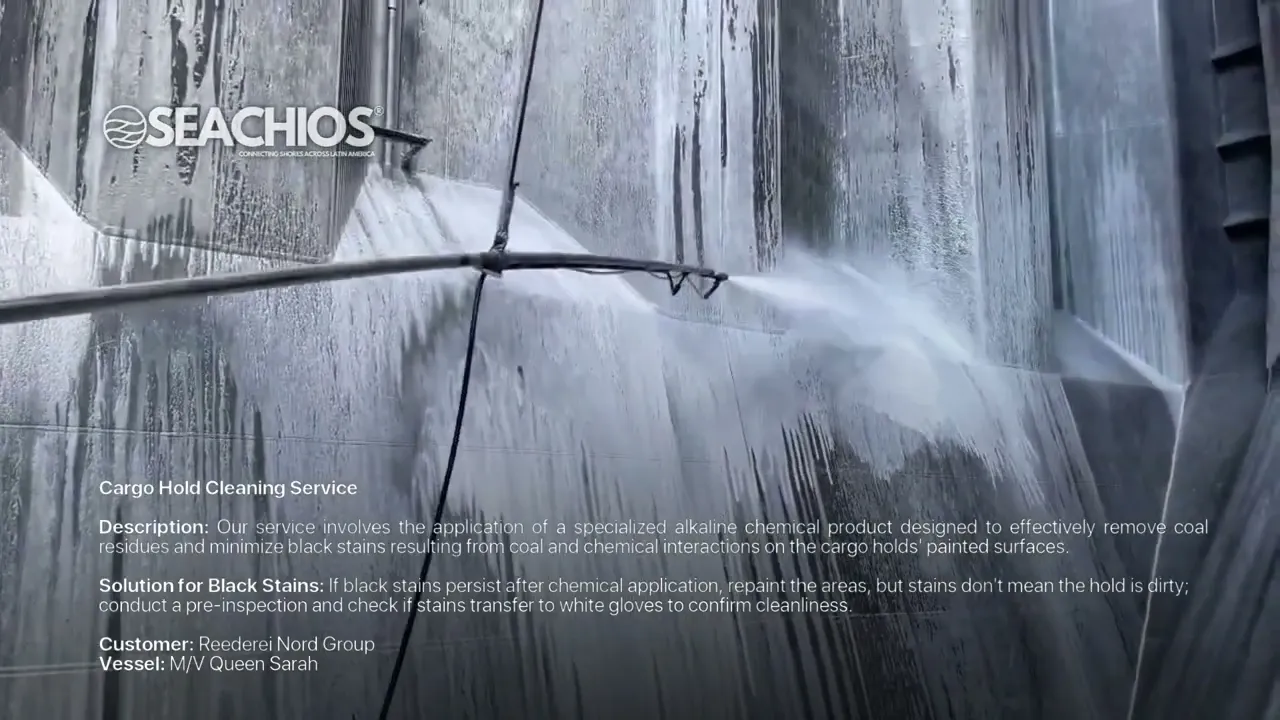

Application of Unitor™ Aquatuff™ (high-alkaline degreaser) by foam lance to vertical stiffeners, webs, and shell plating.

Dwell time controlled to keep surfaces wet; agitation on high-traffic abrasion bands.

Rinse with 500-bar hydrojets; runoff managed to slops.

Post-wash Inspection (26–27 Jul): Blackstain remained as a bonded discoloration despite proper alkaline cleaning and high-energy rinsing.

Transit & Escalation (27–29 Jul, Vila do Conde): Based on acceptance criteria for grain (no visible staining/odour, dry, intact coating, no loose scale), owner opted for repainting. Surfaces were decontaminated, lightly abraded/feathered, stripe-coated on edges, and over-coated per coating maker’s TDS and dew-point control rules.

What We Saw (Field Evidence)

Surface scoring & embedment: Linear scratches and smears where coal was dragged by unloading equipment, forcing fine carbon into the coating matrix and exposed steel (see close-ups).

Gray-coated holds: Light-gray backgrounds amplify visual contrast with carbon black, making even thin bonded films conspicuous.

Localized “lacquered” areas: Shiny, tar-like patches typical of carbonized hydrocarbon films rather than loose dust.

(Photos provided: macro scratches/hand scale; full-hold geometry; foam application; high-pressure rinsing; team in PPE. We can caption them on the page as you wish.)

Why Coal “Blackstain” Persists — The Chemistry & Tribology

Blackstain is not ordinary dirt. It’s a multi-mechanism phenomenon:

Mechanical embedment (tribology):

Under load, hard coal fines and coke-like fragments are forced into micro-pits and coating porosity created by wear, corrosion, or prior blasting profiles.

Abrasion by grabs/shore gear scores the binder, increasing surface energy and giving carbon a key to lock in.

Adsorption & chemisorption on steel/oxides:

Steel surfaces carry iron oxide/hydroxide layers. Aromatic/graphitic domains in coal residues form π–electron interactions with these oxides, leading to strong adsorptive films.

Trace oils/greases from cargo handling act as binding media, wetting the surface and improving carbon adhesion.

Thermal & oxidative transformation:

Voyage temperature cycles (solar heating / night cooling) drive diffusion of low-volatility organics into the coating and promote mild oxidation/polymerization, yielding a thin, carbon-rich varnish.

Once polymerized, this film behaves like a stain within the coating, not a removable soil on top of it.

Why alkalines can’t finish the job:

High-alkaline cleaners (e.g., Aquatuff™, with alkaline builders and surfactants) are excellent at emulsifying fats/oils and dispersing loose carbon, but they do not depolymerize graphitic/aromatic films that have partially cross-linked into or onto the coating/steel.

Aggressive acids are not appropriate: they don’t solubilize carbon films, and they risk etching, flash rust, and salt entrapment—counterproductive before grain.

Bottom line: once carbonaceous films bond and darken the matrix, the reliable remedy—after full decontamination and neutralization—is recoating.

Executive Summary

Vessel: M/V Queen Sarah

Previous cargo: Coal

Next cargo: Grains (Vila do Conde)

Locations & dates: Team embarked 21 Jul 2023 at Pecém; cleaning 22–27 Jul; vessel proceeded to Vila do Conde; repainting 27–29 Jul.

Methods: 500-bar high-pressure water jetting; application of high-alkaline marine degreaser (Unitor™ Aquatuff™) per OEM guidance; freshwater neutralization rinse; controlled waste handling; full repaint decision based on blackstain persistence and grain-clean standard.

Complication: Unloading equipment at Pecém physically abraded coal against the steel, embedding residues and scoring the coating, intensifying blackstain.

Outcome: Holds restored by repainting, achieving visual uniformity, corrosion protection, and charterer acceptance for grain.

Operation Timeline & Scope

Embarkation (21 Jul, Pecém): Shore team mobilized; toolbox talk, JSA/RA, confined-space gas test, and permit-to-work issued.

Gross Cleaning (22–23 Jul): Removal of loose residues; mechanical sweeping; suction and wash-down to expose impacted areas.

Chemical Phase (24–26 Jul):

Application of Unitor™ Aquatuff™ (high-alkaline degreaser) by foam lance to vertical stiffeners, webs, and shell plating.

Dwell time controlled to keep surfaces wet; agitation on high-traffic abrasion bands.

Rinse with 500-bar hydrojets; runoff managed to slops.

Post-wash Inspection (26–27 Jul): Blackstain remained as a bonded discoloration despite proper alkaline cleaning and high-energy rinsing.

Transit & Escalation (27–29 Jul, Vila do Conde): Based on acceptance criteria for grain (no visible staining/odour, dry, intact coating, no loose scale), owner opted for repainting. Surfaces were decontaminated, lightly abraded/feathered, stripe-coated on edges, and over-coated per coating maker’s TDS and dew-point control rules.

What We Saw (Field Evidence)

Surface scoring & embedment: Linear scratches and smears where coal was dragged by unloading equipment, forcing fine carbon into the coating matrix and exposed steel (see close-ups).

Gray-coated holds: Light-gray backgrounds amplify visual contrast with carbon black, making even thin bonded films conspicuous.

Localized “lacquered” areas: Shiny, tar-like patches typical of carbonized hydrocarbon films rather than loose dust.

(Photos provided: macro scratches/hand scale; full-hold geometry; foam application; high-pressure rinsing; team in PPE. We can caption them on the page as you wish.)

Why Coal “Blackstain” Persists — The Chemistry & Tribology

Blackstain is not ordinary dirt. It’s a multi-mechanism phenomenon:

Mechanical embedment (tribology):

Under load, hard coal fines and coke-like fragments are forced into micro-pits and coating porosity created by wear, corrosion, or prior blasting profiles.

Abrasion by grabs/shore gear scores the binder, increasing surface energy and giving carbon a key to lock in.

Adsorption & chemisorption on steel/oxides:

Steel surfaces carry iron oxide/hydroxide layers. Aromatic/graphitic domains in coal residues form π–electron interactions with these oxides, leading to strong adsorptive films.

Trace oils/greases from cargo handling act as binding media, wetting the surface and improving carbon adhesion.

Thermal & oxidative transformation:

Voyage temperature cycles (solar heating / night cooling) drive diffusion of low-volatility organics into the coating and promote mild oxidation/polymerization, yielding a thin, carbon-rich varnish.

Once polymerized, this film behaves like a stain within the coating, not a removable soil on top of it.

Why alkalines can’t finish the job:

High-alkaline cleaners (e.g., Aquatuff™, with alkaline builders and surfactants) are excellent at emulsifying fats/oils and dispersing loose carbon, but they do not depolymerize graphitic/aromatic films that have partially cross-linked into or onto the coating/steel.

Aggressive acids are not appropriate: they don’t solubilize carbon films, and they risk etching, flash rust, and salt entrapment—counterproductive before grain.

Bottom line: once carbonaceous films bond and darken the matrix, the reliable remedy—after full decontamination and neutralization—is recoating.

Executive Summary

Vessel: M/V Queen Sarah

Previous cargo: Coal

Next cargo: Grains (Vila do Conde)

Locations & dates: Team embarked 21 Jul 2023 at Pecém; cleaning 22–27 Jul; vessel proceeded to Vila do Conde; repainting 27–29 Jul.

Methods: 500-bar high-pressure water jetting; application of high-alkaline marine degreaser (Unitor™ Aquatuff™) per OEM guidance; freshwater neutralization rinse; controlled waste handling; full repaint decision based on blackstain persistence and grain-clean standard.

Complication: Unloading equipment at Pecém physically abraded coal against the steel, embedding residues and scoring the coating, intensifying blackstain.

Outcome: Holds restored by repainting, achieving visual uniformity, corrosion protection, and charterer acceptance for grain.

Operation Timeline & Scope

Embarkation (21 Jul, Pecém): Shore team mobilized; toolbox talk, JSA/RA, confined-space gas test, and permit-to-work issued.

Gross Cleaning (22–23 Jul): Removal of loose residues; mechanical sweeping; suction and wash-down to expose impacted areas.

Chemical Phase (24–26 Jul):

Application of Unitor™ Aquatuff™ (high-alkaline degreaser) by foam lance to vertical stiffeners, webs, and shell plating.

Dwell time controlled to keep surfaces wet; agitation on high-traffic abrasion bands.

Rinse with 500-bar hydrojets; runoff managed to slops.

Post-wash Inspection (26–27 Jul): Blackstain remained as a bonded discoloration despite proper alkaline cleaning and high-energy rinsing.

Transit & Escalation (27–29 Jul, Vila do Conde): Based on acceptance criteria for grain (no visible staining/odour, dry, intact coating, no loose scale), owner opted for repainting. Surfaces were decontaminated, lightly abraded/feathered, stripe-coated on edges, and over-coated per coating maker’s TDS and dew-point control rules.

What We Saw (Field Evidence)

Surface scoring & embedment: Linear scratches and smears where coal was dragged by unloading equipment, forcing fine carbon into the coating matrix and exposed steel (see close-ups).

Gray-coated holds: Light-gray backgrounds amplify visual contrast with carbon black, making even thin bonded films conspicuous.

Localized “lacquered” areas: Shiny, tar-like patches typical of carbonized hydrocarbon films rather than loose dust.

(Photos provided: macro scratches/hand scale; full-hold geometry; foam application; high-pressure rinsing; team in PPE. We can caption them on the page as you wish.)

Why Coal “Blackstain” Persists — The Chemistry & Tribology

Blackstain is not ordinary dirt. It’s a multi-mechanism phenomenon:

Mechanical embedment (tribology):

Under load, hard coal fines and coke-like fragments are forced into micro-pits and coating porosity created by wear, corrosion, or prior blasting profiles.

Abrasion by grabs/shore gear scores the binder, increasing surface energy and giving carbon a key to lock in.

Adsorption & chemisorption on steel/oxides:

Steel surfaces carry iron oxide/hydroxide layers. Aromatic/graphitic domains in coal residues form π–electron interactions with these oxides, leading to strong adsorptive films.

Trace oils/greases from cargo handling act as binding media, wetting the surface and improving carbon adhesion.

Thermal & oxidative transformation:

Voyage temperature cycles (solar heating / night cooling) drive diffusion of low-volatility organics into the coating and promote mild oxidation/polymerization, yielding a thin, carbon-rich varnish.

Once polymerized, this film behaves like a stain within the coating, not a removable soil on top of it.

Why alkalines can’t finish the job:

High-alkaline cleaners (e.g., Aquatuff™, with alkaline builders and surfactants) are excellent at emulsifying fats/oils and dispersing loose carbon, but they do not depolymerize graphitic/aromatic films that have partially cross-linked into or onto the coating/steel.

Aggressive acids are not appropriate: they don’t solubilize carbon films, and they risk etching, flash rust, and salt entrapment—counterproductive before grain.

Bottom line: once carbonaceous films bond and darken the matrix, the reliable remedy—after full decontamination and neutralization—is recoating.

Coal blackstain is a thermochemical/tribological imprint: carbonaceous residues become embedded and adsorbed into steel/paint micro-pores. High-alkaline cleaners remove oils and loose carbon but cannot reverse polymerized carbon films—recoating restores aesthetics and protection.

Cleaning Methodology — Controls That Matter

Chemistry: High-alkaline marine degreaser (Unitor™ Aquatuff™) applied by foam to maximize contact time and visual coverage; dilution and dwell as per OEM; never allowed to dry.

Energy: 500-bar hydrojets with fan nozzles, working from top down to prevent re-soiling.

Rinse Quality: Freshwater final rinse to remove alkalinity; surfaces left neutral to slightly alkaline and dry before any coating work.

Waste Handling: Slops contained and disposed via licensed contractor; no discharge to sea (MARPOL V compliance).

Safety: Confined-space entry protocols, atmospheric monitoring, PPE (helmets, goggles/face shields, chemical gloves/boots), anti-slip control, nozzle-man rotation to manage reaction force.

Acceptance Criteria & Decision to Repaint

Grain-clean expectations (widely used by charterers/inspectors) require no previous cargo residues, no discoloration likely to transfer, no loose scale, no odour, dry and visually uniform surfaces. After chemical + mechanical cleaning and joint inspection with ship’s staff, persistent bonded discoloration remained in abrasion bands and corners. To ensure unambiguous acceptance and restore coating integrity where scratches occurred, the owner authorized repainting.

Repainting Workflow (Vila do Conde, 27–29 Jul)

Pre-paint decontamination: Repeat alkaline wash and freshwater rinse; verify dryness and surface temperature vs. dew point.

Localized abrasion/feathering: Remove any weakly adherent coating; stripe coat sharp edges, scallops, cut-outs, and ladder rungs.

Full over-coat: Epoxy hold coating per manufacturer’s TDS and DFT targets; ventilation and cure times observed; QA records taken (WFT/DFT readings).

Result: Uniform color/finish; aesthetics restored and corrosion protection re-established along abrasion pathways.

Root Cause Note — Pecém Discharge Effects

During coal discharge at Pecém, shore equipment dragged and pressed carbon fines against plating, causing linear scoring and deep embedment. These tracks became focal points for blackstain because the micro-damaged coating provides capillaries and high-energy sites where carbon and oils lock in. This explains why staining followed abrasion lines and resisted standard cleaning.

HSQE & Compliance

Risk Management: JSA/RA (HAZID), permit-to-work, confined-space & working-at-height controls.

Environmental: Chemical use within OEM and SDS guidance; slops handled onshore by licensed waste manager with manifest.

Standards Referenced: Good practice aligned with Grain Clean expectations commonly used by charterers/inspectors, ICS guidance for hold cleanliness, and coating maker TDS.

Lessons Learned & Recommendations

Prevent embedment: Coordinate with terminals to minimize abrasive contact during discharge; inspect grabs/chutes for liners.

Early intervention: If staining is spotted early, localized solvent/alkaline cycles plus light abrasion may reduce footprint before thermochemical setting.

Coating resilience: Prefer robust epoxy systems with good abrasion resistance in coal-trading vessels; schedule touch-ups after hard cargoes.

Inspection protocol: Use light-angle visual checks along abrasion paths; record with macro photos for trend analysis.

Acceptance certainty: For grain programs with strict visuals, plan time for repainting when blackstain follows abrasion bands.

Book your next call-out for Cargo Hold Cleaning services!

24/7 mobilization for Pecém, Vila do Conde, Santos, Paranaguá, and more. We confirm team, ETA, and equipment within 30–60 min. Contact us now!

Coal blackstain is a thermochemical/tribological imprint: carbonaceous residues become embedded and adsorbed into steel/paint micro-pores. High-alkaline cleaners remove oils and loose carbon but cannot reverse polymerized carbon films—recoating restores aesthetics and protection.

Cleaning Methodology — Controls That Matter

Chemistry: High-alkaline marine degreaser (Unitor™ Aquatuff™) applied by foam to maximize contact time and visual coverage; dilution and dwell as per OEM; never allowed to dry.

Energy: 500-bar hydrojets with fan nozzles, working from top down to prevent re-soiling.

Rinse Quality: Freshwater final rinse to remove alkalinity; surfaces left neutral to slightly alkaline and dry before any coating work.

Waste Handling: Slops contained and disposed via licensed contractor; no discharge to sea (MARPOL V compliance).

Safety: Confined-space entry protocols, atmospheric monitoring, PPE (helmets, goggles/face shields, chemical gloves/boots), anti-slip control, nozzle-man rotation to manage reaction force.

Acceptance Criteria & Decision to Repaint

Grain-clean expectations (widely used by charterers/inspectors) require no previous cargo residues, no discoloration likely to transfer, no loose scale, no odour, dry and visually uniform surfaces. After chemical + mechanical cleaning and joint inspection with ship’s staff, persistent bonded discoloration remained in abrasion bands and corners. To ensure unambiguous acceptance and restore coating integrity where scratches occurred, the owner authorized repainting.

Repainting Workflow (Vila do Conde, 27–29 Jul)

Pre-paint decontamination: Repeat alkaline wash and freshwater rinse; verify dryness and surface temperature vs. dew point.

Localized abrasion/feathering: Remove any weakly adherent coating; stripe coat sharp edges, scallops, cut-outs, and ladder rungs.

Full over-coat: Epoxy hold coating per manufacturer’s TDS and DFT targets; ventilation and cure times observed; QA records taken (WFT/DFT readings).

Result: Uniform color/finish; aesthetics restored and corrosion protection re-established along abrasion pathways.

Root Cause Note — Pecém Discharge Effects

During coal discharge at Pecém, shore equipment dragged and pressed carbon fines against plating, causing linear scoring and deep embedment. These tracks became focal points for blackstain because the micro-damaged coating provides capillaries and high-energy sites where carbon and oils lock in. This explains why staining followed abrasion lines and resisted standard cleaning.

HSQE & Compliance

Risk Management: JSA/RA (HAZID), permit-to-work, confined-space & working-at-height controls.

Environmental: Chemical use within OEM and SDS guidance; slops handled onshore by licensed waste manager with manifest.

Standards Referenced: Good practice aligned with Grain Clean expectations commonly used by charterers/inspectors, ICS guidance for hold cleanliness, and coating maker TDS.

Lessons Learned & Recommendations

Prevent embedment: Coordinate with terminals to minimize abrasive contact during discharge; inspect grabs/chutes for liners.

Early intervention: If staining is spotted early, localized solvent/alkaline cycles plus light abrasion may reduce footprint before thermochemical setting.

Coating resilience: Prefer robust epoxy systems with good abrasion resistance in coal-trading vessels; schedule touch-ups after hard cargoes.

Inspection protocol: Use light-angle visual checks along abrasion paths; record with macro photos for trend analysis.

Acceptance certainty: For grain programs with strict visuals, plan time for repainting when blackstain follows abrasion bands.

Book your next call-out for Cargo Hold Cleaning services!

24/7 mobilization for Pecém, Vila do Conde, Santos, Paranaguá, and more. We confirm team, ETA, and equipment within 30–60 min. Contact us now!

Coal blackstain is a thermochemical/tribological imprint: carbonaceous residues become embedded and adsorbed into steel/paint micro-pores. High-alkaline cleaners remove oils and loose carbon but cannot reverse polymerized carbon films—recoating restores aesthetics and protection.

Cleaning Methodology — Controls That Matter

Chemistry: High-alkaline marine degreaser (Unitor™ Aquatuff™) applied by foam to maximize contact time and visual coverage; dilution and dwell as per OEM; never allowed to dry.

Energy: 500-bar hydrojets with fan nozzles, working from top down to prevent re-soiling.

Rinse Quality: Freshwater final rinse to remove alkalinity; surfaces left neutral to slightly alkaline and dry before any coating work.

Waste Handling: Slops contained and disposed via licensed contractor; no discharge to sea (MARPOL V compliance).

Safety: Confined-space entry protocols, atmospheric monitoring, PPE (helmets, goggles/face shields, chemical gloves/boots), anti-slip control, nozzle-man rotation to manage reaction force.

Acceptance Criteria & Decision to Repaint

Grain-clean expectations (widely used by charterers/inspectors) require no previous cargo residues, no discoloration likely to transfer, no loose scale, no odour, dry and visually uniform surfaces. After chemical + mechanical cleaning and joint inspection with ship’s staff, persistent bonded discoloration remained in abrasion bands and corners. To ensure unambiguous acceptance and restore coating integrity where scratches occurred, the owner authorized repainting.

Repainting Workflow (Vila do Conde, 27–29 Jul)

Pre-paint decontamination: Repeat alkaline wash and freshwater rinse; verify dryness and surface temperature vs. dew point.

Localized abrasion/feathering: Remove any weakly adherent coating; stripe coat sharp edges, scallops, cut-outs, and ladder rungs.

Full over-coat: Epoxy hold coating per manufacturer’s TDS and DFT targets; ventilation and cure times observed; QA records taken (WFT/DFT readings).

Result: Uniform color/finish; aesthetics restored and corrosion protection re-established along abrasion pathways.

Root Cause Note — Pecém Discharge Effects

During coal discharge at Pecém, shore equipment dragged and pressed carbon fines against plating, causing linear scoring and deep embedment. These tracks became focal points for blackstain because the micro-damaged coating provides capillaries and high-energy sites where carbon and oils lock in. This explains why staining followed abrasion lines and resisted standard cleaning.

HSQE & Compliance

Risk Management: JSA/RA (HAZID), permit-to-work, confined-space & working-at-height controls.

Environmental: Chemical use within OEM and SDS guidance; slops handled onshore by licensed waste manager with manifest.

Standards Referenced: Good practice aligned with Grain Clean expectations commonly used by charterers/inspectors, ICS guidance for hold cleanliness, and coating maker TDS.

Lessons Learned & Recommendations

Prevent embedment: Coordinate with terminals to minimize abrasive contact during discharge; inspect grabs/chutes for liners.

Early intervention: If staining is spotted early, localized solvent/alkaline cycles plus light abrasion may reduce footprint before thermochemical setting.

Coating resilience: Prefer robust epoxy systems with good abrasion resistance in coal-trading vessels; schedule touch-ups after hard cargoes.

Inspection protocol: Use light-angle visual checks along abrasion paths; record with macro photos for trend analysis.

Acceptance certainty: For grain programs with strict visuals, plan time for repainting when blackstain follows abrasion bands.

Book your next call-out for Cargo Hold Cleaning services!

24/7 mobilization for Pecém, Vila do Conde, Santos, Paranaguá, and more. We confirm team, ETA, and equipment within 30–60 min. Contact us now!

More operations

More operations

More operations

Curious for more? Explore additional case studies and see what’s possible for your business too

Sometimes the hardest part is reaching out — but once you do, we’ll make the rest easy.

Opening Hours

Mon to Sat: 9.00am - 8.30pm

Sun: Closed

6:43:51 PM

Services

Legal Department

Sometimes the hardest part is reaching out — but once you do, we’ll make the rest easy.

Opening Hours

Mon to Sat: 9.00am - 8.30pm

Sun: Closed

6:43:51 PM

Services

Legal Department

Sometimes the hardest part is reaching out — but once you do, we’ll make the rest easy.

Opening Hours

Mon to Sat: 9.00am - 8.30pm

Sun: Closed

6:43:51 PM

Services

Legal Department